The Kiev exhibition, which in many ways is an annual indicator of the current industrial potential of Ukraine.

For many years, TaeguTec Ukraine in liaison with the Group of Companies ETC “VariUs” set the rhythm and setting benchmarks in the field of engineering development in Ukraine, demonstrating at the Forum’s largest stand its own design achievements and developments of the staff of the Engineering Center over the past year. It also organizes during the exhibition international meetings of successful and developing machine builders of Ukraine with representatives of the best world manufacturers of metalworking equipment, metal cutting tools, tooling and software for CNC machines. Introduces to the management of manufacturing enterprises the production optimization techniques using IT solutions from the field “4.0 industry”.

Thanks to the experience and knowledge of technical specialists of TaeguTec Ukraine and the Group of Companies “VariUs” have been successfully solving the production problems of most of the engineering enterprises of Ukraine for 15 years. Among the long-standing Partners of the ETC are such flagships of domestic engineering as PJSC “Hydrosila Group”, JSC “Motor Sich”, GP “KhMP FED”, and GE “Malysheva Plant ”, State Enterprise ZhMP “VIZAR”, LLC “PromTehnoGruppa”, enterprise “TRIZ”, company “RAKS” and many other enterprises of the public and private sector.

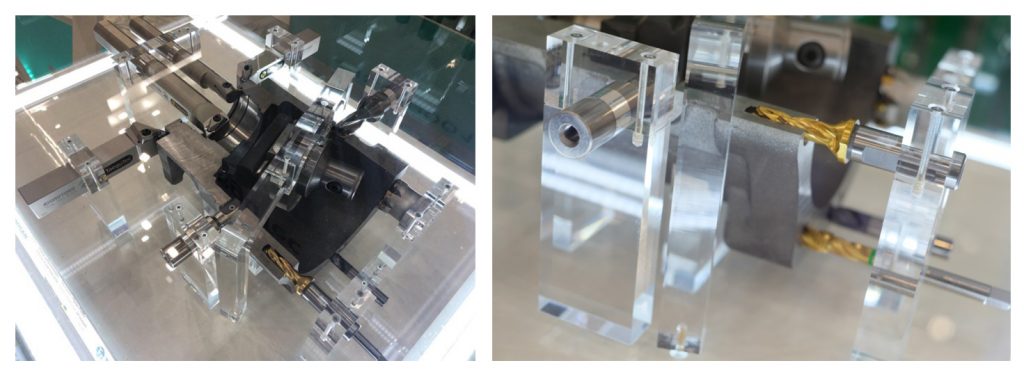

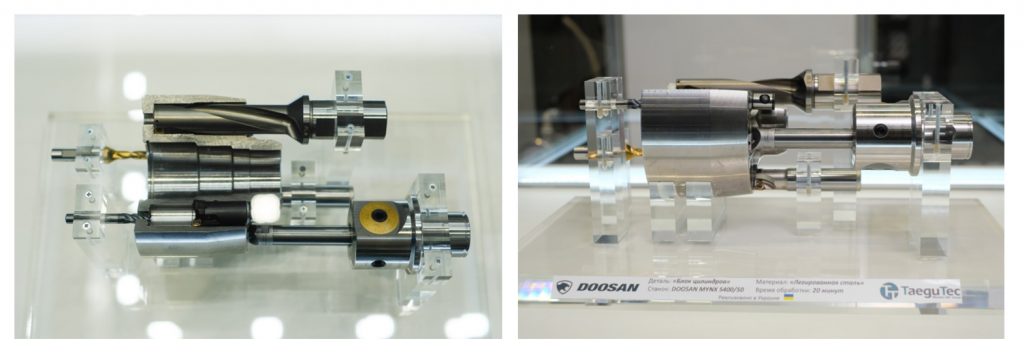

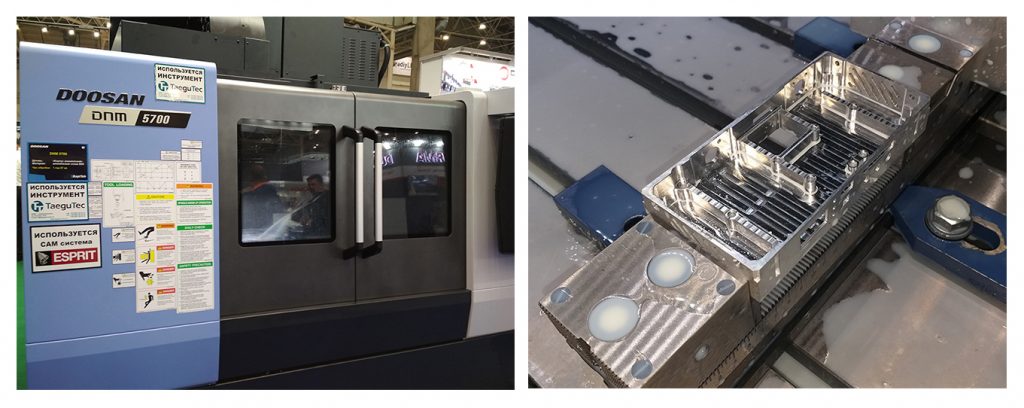

This year at the booth of the Group of Companies were presented some of the most technologically interesting projects implemented on a “turnkey” basis in Ukraine in 2018-2019. Illustrative and attracting the special attention of many technologists of the enterprises was a new exposition of complex units that are mass-produced at the high-profile production sector of PJSC “Hydrosila APM” (Kropyvnytskyi City), manufactured on sophisticated multi-purpose DOOSAN equipment using the innovative TaeguTec tools (Republic of Korea).

Part: Motor case

Machining material: cast iron СЧ20

Machine model: DOOSAN PUMA SMX 2600, machining time — 18 minutes

Machine model: DOOSAN PUMA 280, machining time — 7 minutes

Used tools: TaeguTec

Part: Cylinder assembly

Machining material: alloyed steel

Machine model: DOOSAN MYNX 5400/50, machining time — 20 minutes

Used tools: TaeguTec

During the Kiev exhibition 2019, were held negotiations and were outlined plans for the introduction of new instrumental solutions to increase machining productivity and to reduce machining costs with several Ukrainian machine-building enterprises.

An important result of the Forum-2019 was the approval by the specialists of TaeguTec Ukraine and Engineering Center “VariUs” together with representatives of the “Hydrosila Group” enterprise of a list of events to improve the existing processing technologies for products such as “Valve body”, “Plunger”, “Motor case” and other parts in order to achieve more high performance. From the General Director of “Hydrosila APM”, the main condition for cooperation in 2020 was announced: «… to ensure a short payback period and high efficiency of investments already made in production facilities.»

In order to accomplish this task, the IT department of the Engineering Center “VariUs” proposed solutions that would allow “Hydrosila” company to reduce existing production costs by introducing technologies from the field “4.0 industry”, which means to increase work efficiency — without any additional investments Customer’s side at all. Solutions such as the introduction of the MATRIX automated tool warehouse with a pre-programmed role allocation and the Remote Equipment Efficiency Monitoring System (“VariUs” own software development) are already being tested and partially implemented. More efficient and cost-effective tool solutions from the SfeedTec line from TaeguTec Company are being introduced, it is leading the work to update the capabilities of the technologist’s automated workstations based on CAM ESPRIT software.

Part “Cylinder block” Part “Valve body”

Moreover, by General Director of “Hydrosila” Holding were given Technical tasks related to the production of new products for the “Hydrosila APM” (Kropyvnytskyi City) and “Hydrosila MZTG” (Melitopol City) to specialists from the departments of the chief technologist of TaeguTec Ukraine and the software development departments of the ETC “VariUs”.

No less ambitious tasks were set at the exhibition by representatives of the enterprises of “Metinvest” Group, PJSC “FED”, PJSC “DPM” and other government and private companies that already have positive cooperation experience with TaeguTec Ukraine company and the Group of companies ETC “VariUs”. There were discussed new projects for the production of complex products for general engineering field, the tasks of the defense complex and the aerospace field.

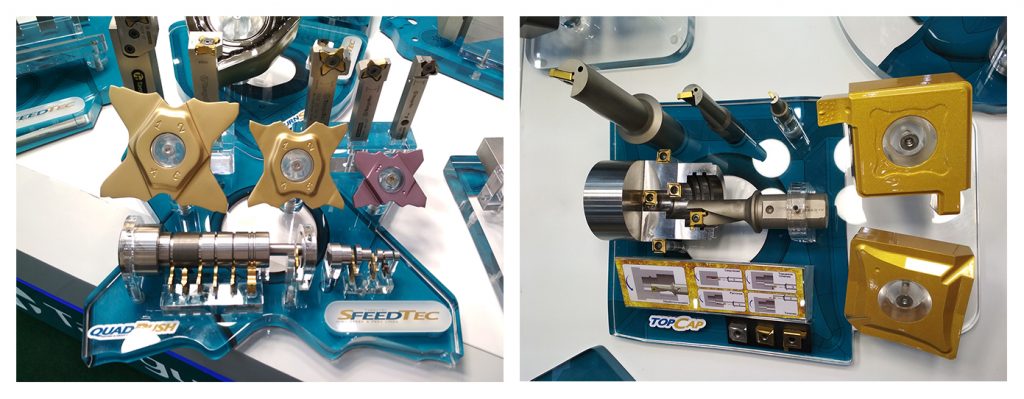

With the representatives of “NZTO” enterprise, which have been operating DOOSAN equipment for three-shift working conditions for more than 8 years, was discussed a plan of implementation a new tools from the SfeedTec line. Last developments in this series will increase the productivity of processing parts such as the «Floating Needle» and other products from hardened materials, the machining of which was carried out directly in the exhibition.

The good news was the expansion of the product range of TaeguTec and ISCAR thread processing tools. This allows technologists from “VariUs”, “TaeguTec Ukraine” and “ISCAR Ukraine” companies to propose and implement the latest and most effective solutions for such modern developing enterprises as PJSC “KCDBV” and other “reinforcing” plants.

For the second time in 2019, a delegation of IMC Group (Tefen, Israel) visited Ukraine, the second largest metalworking tool company in the world. The IMC structure includes 13 plants on all continents that manufacture and supply a dynamic line of high-precision carbide tools for metal processing. IMC factories produce a wide range of carbide tools covering most applications, as well as provide engineering and manufacturing solutions for key industries all around the world. Many innovative products designed specifically for the needs of customers have made IMC Group a world leader in the automotive, marine, aerospace, metallurgical and heavy industries.

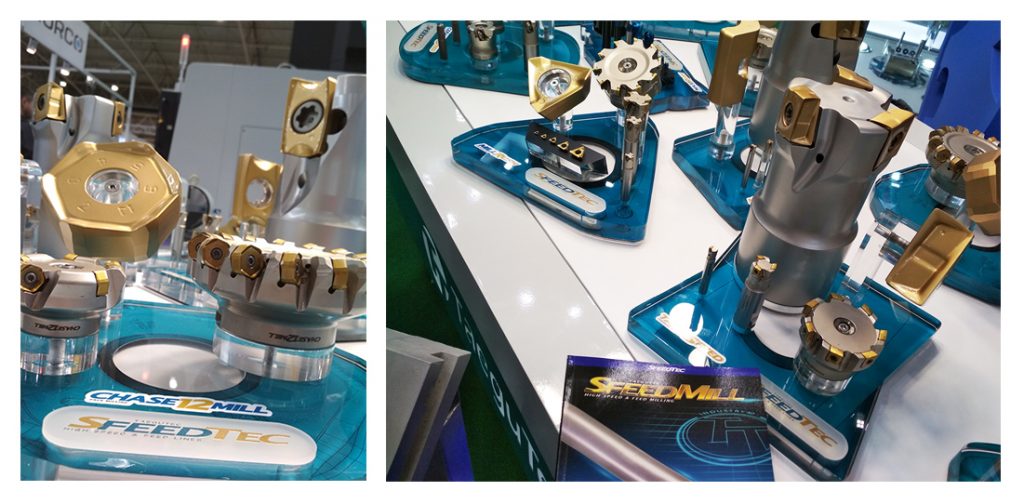

IMC technical advisers Yuri Sorkin and Sergey Chistyakov during four days of the exhibition were held many dozens of meetings with representatives of Ukrainian. A series of technical consultations and exchange of experience was held about the work of IMC company with leading world manufacturers: Posco, Hyundai, SKF, BMW, Airbus, Boeing, ArcelorMittal, Royal Dutch Shell, Vyksa Steel Works Plant, Nizhnyaya Salda Metallurgical Plant, Pervouralsky Novotrubny Plant, etc. Yuri and Sergey provided the maximum information and the best technological solutions for metal processing and, in particular, economical threading from the TaeguTec, Iscar, Tungaloy lines. And, of course, the main emphasis was indicated on the ultra-modern SFEEDTEC line from TaeguTec (Republic of Korea). In all cases, the purpose of the meeting was to increase the productivity and quality of the customer’s products with reducing its cost.

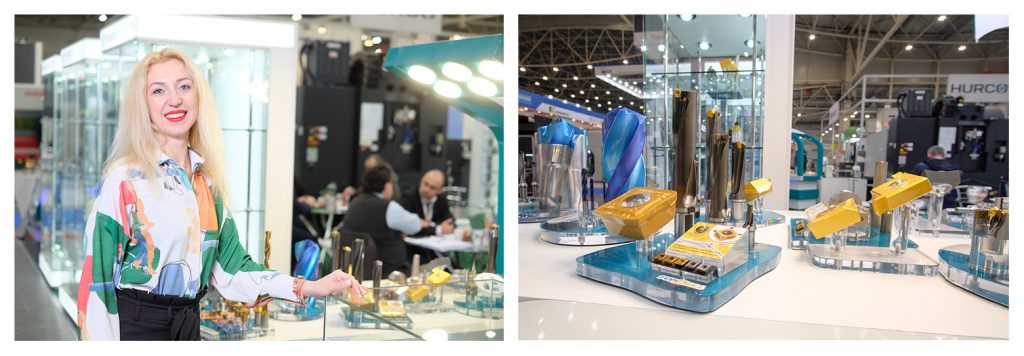

The exposition of TaeguTec metal cutting tools was unique this year. In addition to the popular for many years such series as RhinoTurn, QuadRush, TopDrill and others, a completely new modern line was introduced — SfeedTec. This is the latest generation tool that provides work at higher speeds and feeds, it ahead of any tool manufacturer by several years in its capabilities.

The 2019 generation tool offers a wide range of solutions — for a wide variety of metalworking tasks:

Among the milling product innovations:

Turning product innovations was presented by following:

A unique feature of the booth of the Group of Companies “VariUs” is a demonstration of the continuous operation of several models of equipment. This year, Forum visitors got acquainted with the capabilities of eight models of DOOSAN metal-cutting machines. Throughout all the exhibition, processing of complex parts was carried out, which was accompanied by consultation of the guests by technologists and service engineers of the company “VariTec”.

A new standard in the design of vertical machining centers, providing increased productivity, high precision and excellent machining quality with an economical price for machines among this series.

On the milling processing center was carried out a demonstration of processing a complex product with a monolithic carbide tool specially selected for high-speed processing of non-ferrous metals.

Possibilities of the model:

• maximum spindle speed – 12 000 rpm

• machining was carried out without a rotary table.

In addition, guests of the DOOSAN-Varitec booth could compare the processing features of this product with / without a GSA + CNC 250R rotary table with a reinforced tailstock and an intermediate plate. For this, a simulation was organized on a tablet near to the machine.

Part “Aluminum body frame”, machining material — aluminum В95

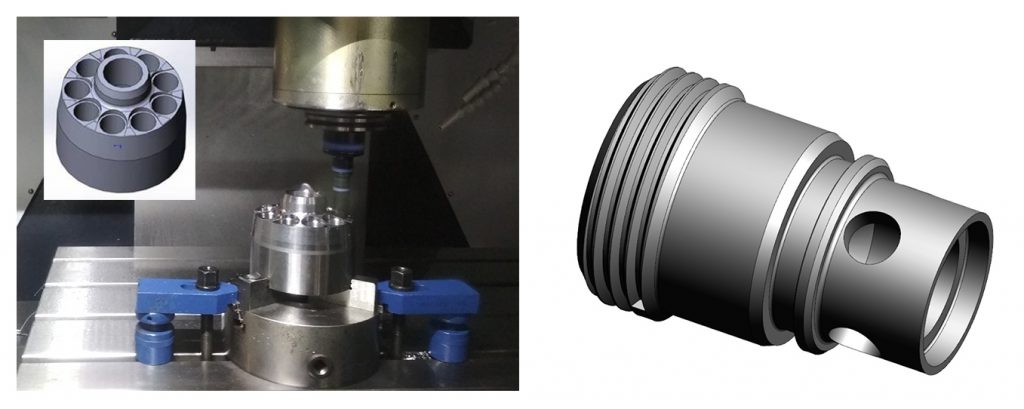

This high-power equipment was used to demonstrate the high-precision machining of holes in carbon steel parts at the highest cutting conditions. Innovations in the construction of the bed together with a powerful spindle made it possible to achieve high-precision and high-performance machining in conditions of heavy milling.

Part «Cylinder block”, machining material – carbon steel 45. Manufacturer: PJSC “Hydrosila APM”

This machine was used to demonstrate the turning and milling machining of a complex miniature product using the automatic bar feeder LNS “Alpha 320 S3”.

Part “Bridle”, alloy steel

Possibilities and features of the machine model PUMA ST 20GS:

• complete machining of a part from a bar with a maximum cutting speed for the manufacture of small parts

• BUILT-IN engine

• maximum speed – 10 000 rpm

• machining of high-precision products of small sizes.

This lathe center has an attractive price, despite the fact that it is equipped with a multi-position turret, a modern Fanuc CNC system and a full-fledged Y axis. The machine is designed to machine parts in the chuck, in the centers and with bar feed through the spindle.

At the exhibition were performed high-performance machining of the part “Valve body” and a demonstration of almost all types of lathe machining:

• rough turning

• fine turning

• grooving

• threading

• drilling a central hole

• boring of the central hole

• diameter drilling

• cutting.

Part “Valve body”, machining material – carbon steel 45. Manufacturer: PJSC “Hydrosila APM”

The superior machining accuracy and advanced features of the Multifunctional Rigid Center PUMA series provide a significant increase in productivity. Was demonstrated the cutting of teeth with the highest speed by Morse end mills (low cost with excellent tool quality).

Machine model features:

• obtaining high quality surfaces and dimensions «under the bearing»

• grooving for snap rings

• work in the steady rest.

Part: «Floating Needle», machining material — steel 4Х5МФС. Manufacturer: PJSC “NZTO”

Annually, the booth of the VariTec company is visited by representatives of the supplier company — DOOSAN MACHINE TOOLS CO., LTD. Throughout all the exhibition period, delegates from the Republic of Korea – Mr. Harin Choi (Sales Deputy General Manager). and Mr. Jake Lee (Sales Assistant Manager) — consulted regular and new customers of the Group of Companies “VariUs”.

DOOSAN specialists answered to complex questions from visitors of the Forum and introduced guests with new equipment models. The guests of the booth could get expert advices on choosing the most optimal machine configuration — for each specific task discussed within the framework of Industrial Forum-2019.

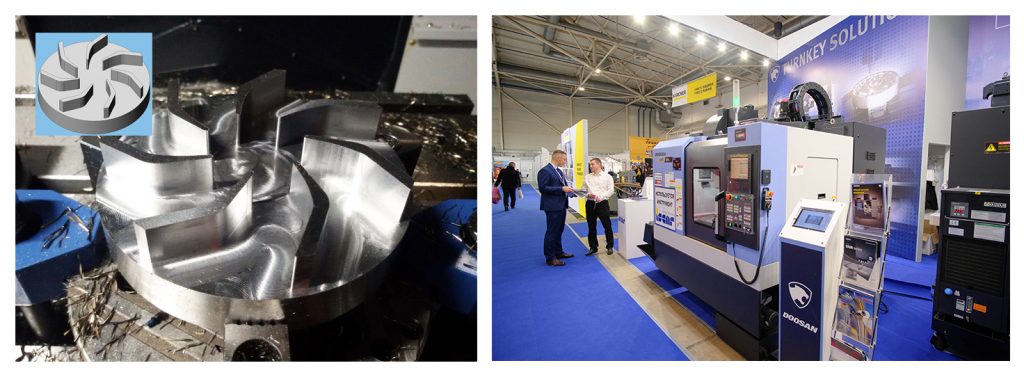

The “ISCAR Ukraine” engineering company specialists quite interestingly implemented intellectual complex projects using the “TURNKEY SOLUTION” method, when DOOSAN equipment was offered from a single supplier along with a tool from the world leader in the manufacture of metalworking solutions – ISCAR. Three DOOSAN machines made real-time machining of complex configuration parts. Visitors of the booth were convinced of the effectiveness of the tandem of the presented equipment with the highest class tools ISCAR (Israel).

The “ISCAR Ukraine” engineering company specialists quite interestingly implemented intellectual complex projects using the “TURNKEY SOLUTION” method, when DOOSAN equipment was offered from a single supplier along with a tool from the world leader in the manufacture of metalworking solutions – ISCAR. Three DOOSAN machines made real-time machining of complex configuration parts. Visitors of the booth were convinced of the effectiveness of the tandem of the presented equipment with the highest class tools ISCAR (Israel).

At the milling machining center was machined the part “Iron Man Mask” using the ISCAR cutting tools in two operations:

• high-milling rough machining with the new series of milling cutters with square inserts SOMT

• finish machining using high-precision carbide spherical cutters.

The selected machine model with a maximum spindle speed of 12 000 rpm allowed us to demonstrate the processing of complex curved surfaces.

Part “Iron Man Mask”, machining material — carbon steel 45

At the milling machining center was carried out high-speed machining of the “Impeller” part using the modern method — trochoid milling (milling with a small contact width). The tool path was calculated using the ProfitMilling strategy in the ESPRIT CAM-system. The workpiece was machined with ISCAR high-speed carbide milling cutter with seven cutting teeth.

Part “Impeller”, machining material — carbon steel 45

This model is the largest among all compact machines of the Lynx series and allows you to machine parts with a diameter up to 370 mm with a length up to 712 mm. Engine power and construction rigidity of the model made it possible to demonstrate the capabilities of the ISCAR cutting tools in aggressive machining conditions and to ensure high quality curved surfaces on the steel part “Railway Wheel”.

Part “Railway Wheel”, machining material – carbon steel 45Part “Railway Wheel”, machining material – carbon steel 45

At the booth of Group of Companies “VariUs”, was traditionally represented the ESPRIT CAM-system (from DP Technology Company, USA) which is used for programming CNC machines. Presentations were leaded and questions were answered by a special guest of the booth — Nicolas Gubala — the head of partner distribution channels in Europe of DP Technology Corporation.

Exactly in the ESPRIT CAM-system the technologists of the Group of Companies “VariUs” prepared control programs and simulated part processing for demonstration at the exhibition. The same complex is supplied to customers as the main CAM-system to increase automation of production and increase the capabilities of the enterprise.

A wide range of processing cycles allows to prepare and simulate processing on any type of machines:

• lathe machines

• lathe-milling machines

• milling machines with different numbers and combinations of axes.

The visitors of the exhibition were greatly interested in the synchronized demonstration of video simulation of machining and the actual machining proses of the part on the equipment.

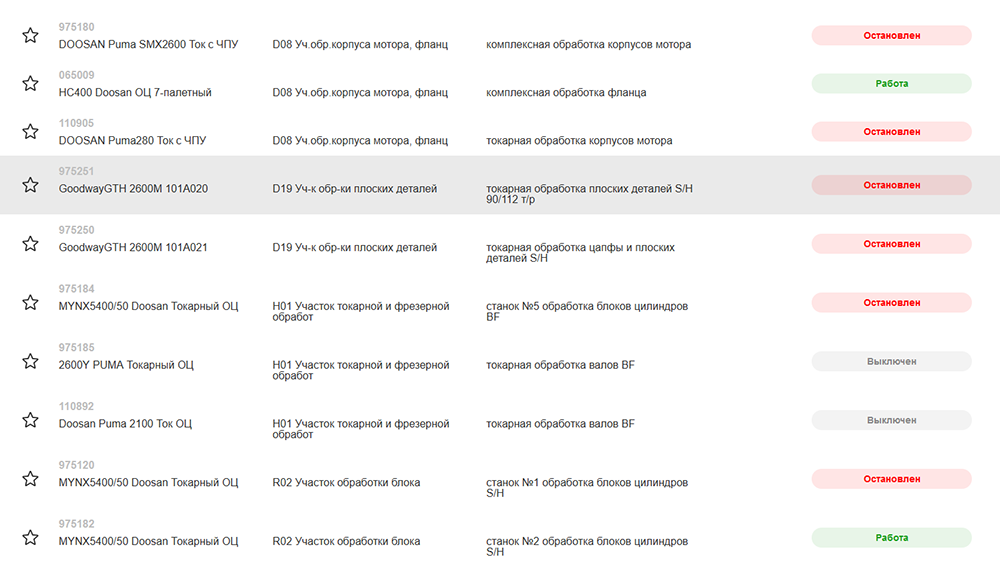

To increase the efficiency of use of metalworking equipment, Group of Companies “VariUs” has developed and implements in Ukrainian enterprises the hardware and software complex «System for monitoring the efficiency of equipment use».

This complex allows you to collect information from Fanuc CNC frames in real time. There are saved records of equipment operating conditions, used CNC programs, operation errors and much more.

Based on the collected information, the analytical core of the system builds reports on the status of equipment in real time, as well as consolidated reports on the loading of equipment and operators for the selected monitoring period.

The specialists of Group of Companies “VariUs” are sure that this system gives customers the opportunity of more effectively use the capabilities of the equipment supplied.

During 2019, within the framework of two major engineering projects, this complex was successfully implemented in two operating engineering enterprises of Ukraine:

• “Hydrosila APM” (Kropivnitsky City)

|

Quantity |

Machine model |

|

1 |

DOOSAN Puma SMX2600 |

| 1 | DOOSAN PUMA 280 |

| 2 | DOOSAN PUMA 2600Y |

| 1 | DOOSAN PUMA 2100 |

| 1 | DOOSAN PUMA TT 1800 |

| 4 | DOOSAN LYNX 220 |

| 1 | DOOSAN HC 400 |

| 5 | DOOSAN MYNX5400/50 |

| 2 | GOODWAY GTH 2600M |

• Government Enterprise ZhMP “VIZAR”, (Vishnevoe City)

| Quantity | Machine model |

| 3 | DOOSAN LYNX 300M |

| 1 | DOOSAN LYNX 220LC |

| 1 | DOOSAN PUMA GT2600LM |

| 1 | DOOSAN PUMA 4100B |

| 2 | DOOSAN DNM 5700 |

| 1 | DOOSAN LYNX 2100a |

| 2 | DOOSAN LYNX 2100LYC |

Also, it was carried out several deliveries of the complex as part of the acquisition by the customer of new DOOSAN equipment.

The development and implementation of the complex is carried out by the IT department of the ETC “VariUs”.

The exposition of the ALPA measuring tools (Italy) traditionally has attracted increased interest from visitors.

For customers, was introduced the equipment manufactured in 2019 year, as well as measuring instruments well-established at Ukrainian enterprises that were released in 2018 and already tested in real production.

In addition to the presentation and testing of measuring tools, was presented an updated catalog of the Silver Line tool series, highlighting technological innovations and “hot” positions of 2019.

ALPA exposure included:

For promptly resolve of technical issues and presentation of new PROMO 2020 tools, the exhibition in Kiev was visited by a delegation of the ALPA Company, consisting of Mr. Giovanni Dotti — ALPA Director and Mr. Davide Martini, the company’s leading specialist.

The visitors of the Industrial Forum showed a high interest in the DIGITAL series of fine boring heads, manufacture of Swiss Tools company (Switzerland). The convenience of the proposed equipment is fine-tuning with an accuracy of 1 μm, which helps to reduce the setup time and to get high quality workpieces at an economical cost.

The exposition of band saw blades included samples of processed workpieces from various materials and profile shapes for blank sections: granite, steel, composite materials, complex shaped blanks and others. The guests of the Booth were able to get acquainted with the new products of this year. For example, with the universal bimetallic tape blade VariUs art.157 M42 — the best choice for cutting workpieces of various shapes and sizes.

In addition, samples of the high-performance and unique Maija milling tools were presented: single-sided and double-sided disc milling cutters. This tool was first presented at the exhibition in 2018 and has already been evaluated by Ukrainian experts for increased safety and environmental friendliness.

We thank to the Partners of TaeguTec Ukraine and Group of Companies “VariUs”, the organizers and guests of the Industrial Forum!

See you at your factories and congratulations on the upcoming New Year 2020!

TaeguTec Ukraine — equipment + tools + technology + CAD / CAM + service + training – all from one company!

Any information of interest on TaeguTec tool solutions can be obtained by contacting the office of TaeguTec Ukraine.

Always at your service:

Related materials: